- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

Whatservice company, we combine practical experience and legal norms to provide professional advice to foreign - trade enterprises from the perspectives of liability determination and risk prevention.is Import Inspection?

Import inspection is a prerequisite for customs clearance of goods. Normally, if a batch of imported goods falls within the scope of statutory inspection, mandatory inspection is required (conducted by the General Administration of Quality Supervision, Inspection and Quarantine); if not within the statutory inspection scope, random sampling, supervision, and management may be applied to imported goods.

Three Major Components of Import Inspection

Three main parts

Currently, import inspection consists of three main parts: 1. Declaration; 2. Sampling; 3. Inspection.

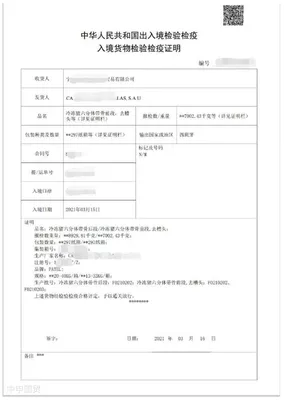

Inspection Application:The importer completes the Inspection and Quarantine Certificate for Entry Goods and prepares relevant documents, then applies for inspection at the port inspection agency and pays the inspection fees.

Sampling:Sampling must be conducted according to national standards, and consigned goods must not be moved before passing inspection.

Inspection:If goods are found non-compliant or incomplete during inspection, the importer may request an inspection report from customs authorities and file a claim accordingly.

service expert with 20 years of industry experience, this article will systematically analyze the core points of clothingDocuments Required for Import Inspection

Information required

After completing relevant forms, the importer must also submit supporting materials during import inspection.

For quality appraisal applications, foreign quality certificates, manuals, technical data, etc. must be provided; for sample transactions, transaction samples must also be submitted.

For weight or quantity appraisal applications, packing lists and weight memos must be provided.

For damage inspection appraisal, tally certificates and evidence of damage/shortage incidents must be provided.

For reinspection requests, detailed acceptance records and inspection result sheets approved by the importer must be provided.

When evaluating imported goods based on component purity and official quantity, both quality appraisal and weight appraisal should be conducted simultaneously.

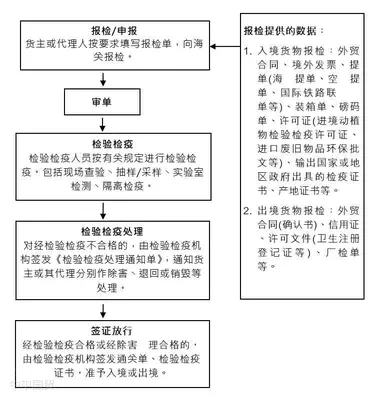

Main Process of Import Inspection

Inspection process

Label pre-approval. Prepare materials for label pre-approval, typically completed within one working day. If not approved, re-pre-approval is required.

On-site declaration. After passing pre-qualification, prepare declaration materials, usually completed within one working day.

Arrange inspection and sampling. Schedule one working day in advance. If sampling inspection is needed, inspectors will sample and issue sampling certificates; if not required, goods will be released directly after passing inspection.

Label filing. Present pre-made goods labels during inspection and provide copies.

Sample testing. Inspection and quarantine department personnel send samples to labs for analysis (half-day or one-day), with results available within 15 working days.

Submit goods list and issue health certificate. After passing inspection, the importer submits the goods list to the lab to obtain a health certificate (5-7 working days).

. For more relevant information and content, welcome to followWhat materials are required for import inspection? What is the specific process?Zhongshen International TradeDangerous Goods.

Related Recommendations

? 2025. All Rights Reserved. 滬ICP備2023007705號-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912